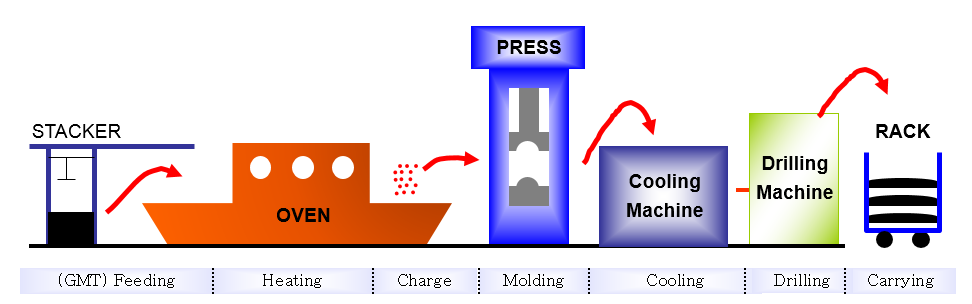

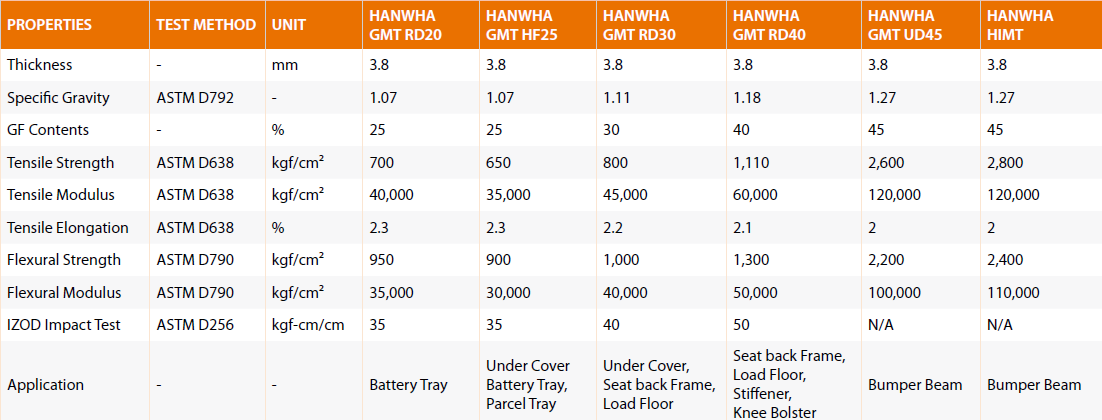

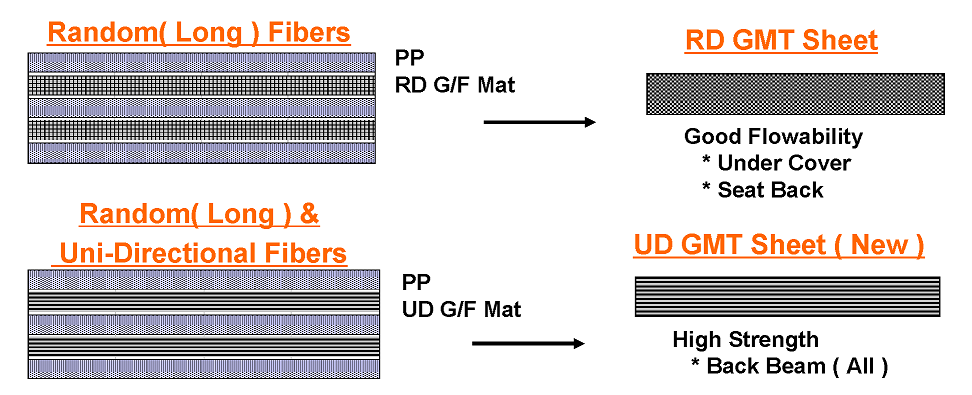

Mass production of StrongLite began in 1995, and it has become highly regarded for its advanced technological properties and quality. Since 2009, StrongLite has held 70% of the global market share for GMTs. It comprises sheet form lightweight composites, and is produced using a polypropylene matrix reinforced by glass fiber mat. It binds exceptionally well and is comparable in strength to steel, but with 20-25% less mass. Our GMTs accommodate complex design features while providing significant impact resistance. They are easy to assemble and reprocess, and are prized for their strength and lightweight nature, making them the perfect structural component to replace steel and reduce mass. Common end products include: undercovers protecting the bottom of the automobile, tough plastic bumpers, and seat back frames. GMT undercovers are also effective in reducing road noise.

-

Rear Bumper Beam

Rear Bumper Beam -

FEM Carrier

FEM Carrier -

Seatback Frame

Seatback Frame